Izikhonkwane zekhonkrithi zentsimbi eqinileyo

Isicelo

Siyazi ukuba xa kufikwa kwiiprojekthi zokwakha, ukuchaneka kunye nokuguquguquka kubaluleke kakhulu. Izikhonkwane zethu zekhonkrithi yentsimbi eqinileyo ziyafumaneka ngobude obahlukeneyo, ububanzi kunye neentlobo zeentloko, nto leyo eyenza ukuba zifaneleke kwiintlobo ngeentlobo zezicelo. Nokuba ubopha izinto zomthi, zesinyithi okanye zomthi kwiindawo zekhonkrithi, ezi zikhonkwane zihambelana kakuhle ukuqinisekisa ukuba zilungele iimfuno zakho ezithile.

Uphawu

Ngenxa yoyilo lwazo olugqwesileyo, izikhonkwane zethu zekhonkrithi zentsimbi eqinileyo zinika amandla akhethekileyo okubamba. Ingongoma eqingqiweyo igqobhoza ngokulula imiphezulu yekhonkrithi ngaphandle kokubangela ukuqhekeka okanye ukuqhekeka okungafanelekanga, iqinisekisa inkqubo yokufaka engenamthungo. Ngecandelo lazo elinqamlezileyo elimile okwedayimani, ezi zikhonkwane ziphucula indawo yoqhagamshelwano ngaphakathi kwekhonkrithi, zibonelela ngokubamba okungenakuthelekiswa nanto kunye nozinzo xa sele zifakiwe. Oku kwenza ukuba kube namandla okuthwala umthwalo okwandisiweyo, okuphucula ukuthembeka kwesakhiwo seeprojekthi zakho.

Ukuzinikela kwethu kumgangatho ophezulu kudlulela ekunyangweni komphezulu wezikhonkwane zethu zekhonkrithi zentsimbi eqinileyo. Ngenkqubo ecokisekileyo, ezi zikhonkwane ziyafakwa kwi-galvanization, zibonelela ngomaleko owongezelelweyo wokhuseleko kumhlwa kunye nokugqwala. Olu gqubuthelo lwe-galvanized luyandisa kakhulu ubomi bezikhonkwane, luqinisekisa ukusebenza okuhlala ixesha elide nokuthembekileyo nakwiindawo ezinzima. Ukongeza, ukugqitywa okugudileyo kwezi zikhonkwane kunciphisa ukungqubana ngexesha lokufakelwa, okuvumela ukusetyenziswa okusebenzayo nokulula.

Izinto ezisetyenzisiweyo

| USus | C | Si | Mn | P | S | Ni | Cr | Mo | Cu |

| 304 | 0.08 | 1.00 | 2.00 | 0.045 | 0.027 | 8.0-10.5 | 18.0-20.0 | 0.75 | 0.75 |

| 304Hc | 0.08 | 1.00 | 2.00 | 0.045 | 0.028 | 8.5-10.5 | 17.0-19.0 |

| 2.0-3.0 |

| 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.029 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | 0.75 |

| 430 | 0.12 | 0.75 | 1.00 | 0.040 | 0.030 |

| 16.0-18.0 |

|

Iimpawu zeWire zaMazwe ahlukeneyo

| mm | I-CN.WG | I-SWG | I-BWG | AS.WG |

| 1G |

|

| 7.52 | 7.19 |

| 2G |

|

| 7.21 | 6.67 |

| 3G |

|

| 6.58 | 6.19 |

| 4G |

|

| 6.05 | 5.72 |

| 5G |

|

| 5.59 | 5.26 |

| 6G | 5.00 | 4.88 | 5.16 | 4.88 |

| 7G | 4.50 | 4.47 | 4.57 | 4.50 |

| 8G | 4.10 | 4.06 | 4.19 | 4.12 |

| 9G | 3.70 | 3.66 | 3.76 | 3.77 |

| 10G | 3.40 | 3.25 | 3.40 | 3.43 |

| 11G | 3.10 | 2.95 | 2.05 | 3.06 |

| 12G | 2.80 | 2.64 | 2.77 | 2.68 |

| 13G | 2.50 | 2.34 | 2.41 | 2.32 |

| 14G | 2.00 | 2.03 | 2.11 | 2.03 |

| 15G | 1.80 | 1.83 | 1.83 | 1.83 |

| 16G | 1.60 | 1.63 | 1.65 | 1.58 |

| 17G | 1.40 | 1.42 | 1.47 | 1.37 |

| 18G | 1.20 | 1.22 | 1.25 | 1.21 |

| 19G | 1.10 | 1.02 | 1.07 | 1.04 |

| 20G | 1.00 | 0.91 | 0.89 | 0.88 |

| 21G | 0.90 | 0.81 | 0.81 | 0.81 |

| 22G |

| 0.71 | 0.71 | 0.73 |

| 23G |

| 0.61 | 0.63 | 0.66 |

| 24G |

| 0.56 | 0.56 | 0.58 |

| 25G |

| 0.51 | 0.51 | 0.52 |

Izikhonkwane zoYilo oluSetyenzisiweyo

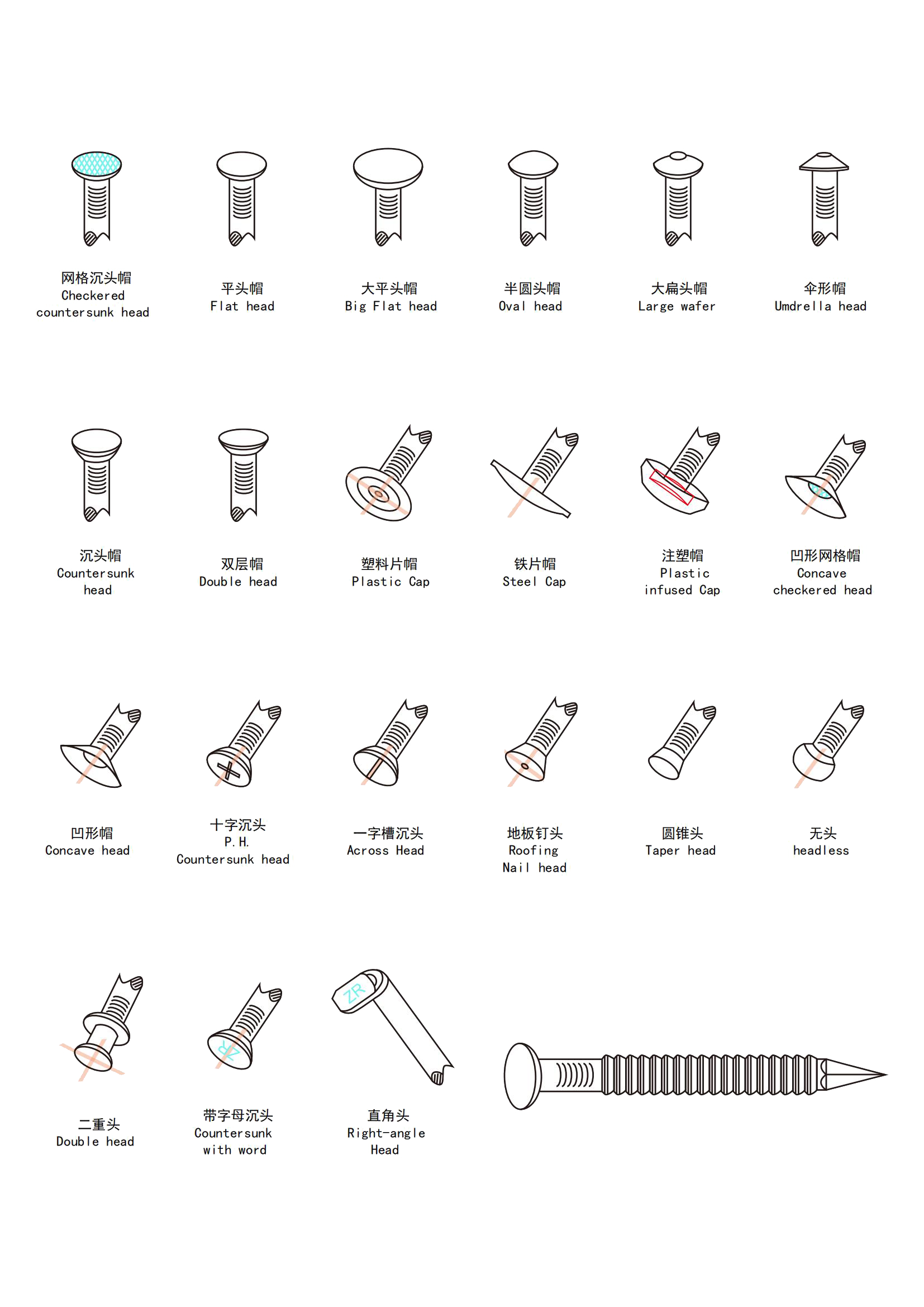

Uhlobo kunye nokuma kweNtloko yezipikili

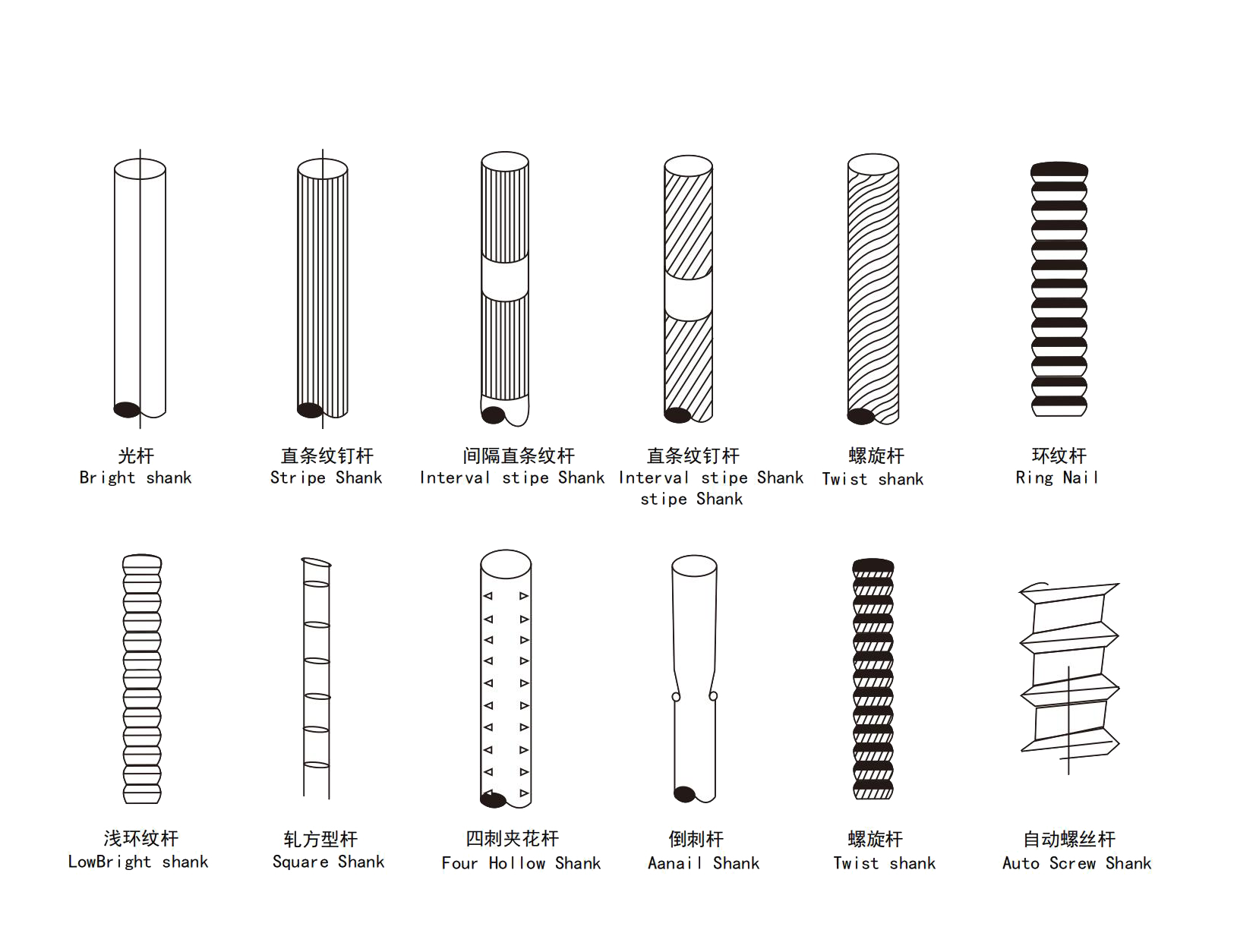

Uhlobo kunye nokuma kwe-Nails Shank

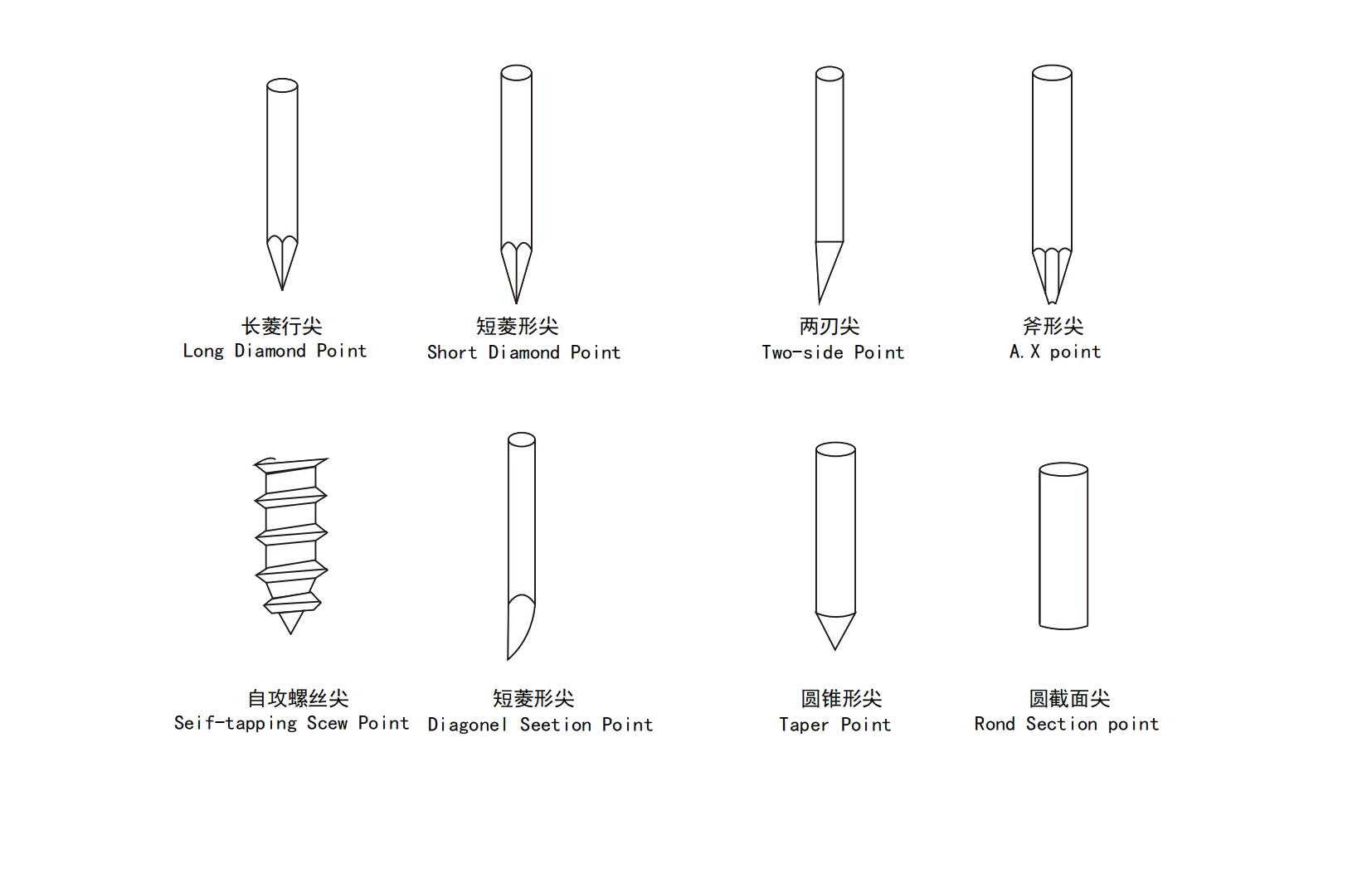

Uhlobo kunye nokuma kwezipikili Inqaku

I-Yihe Enterprise yinkampani egxile kuyilo kunye nokuveliswa kwezikhonkwane, izikhonkwane ezisikwere, imilo yeenzipho, zonke iintlobo zezikhonkwane ezinemilo ekhethekileyo kunye nezikrufu. Ukukhethwa kwezinto zezikhonkwane zentsimbi yekhabhoni esemgangathweni, ubhedu, i-aluminium kunye nentsimbi engatyiwayo, kwaye inokwenza unyango olushushu, olushushu, olumnyama, ubhedu kunye nolunye umphezulu ngokwemfuno yabathengi. Isikrufu esiphambili sokwenza izikrufu zoMatshini ezenziwe eMelika ze-ANSI, izikrufu zomatshini ze-BS, i-bolt corrugated, kubandakanya i-2BA, i-3BA, i-4BA; izikrufu zomatshini ezenziwe eJamani ze-DIN (DIN84/ DIN963/ DIN7985/ DIN966/ DIN964/ DIN967); Uthotho lwe-GB kunye nezinye iintlobo zeemveliso ezisemgangathweni nezingezizo ezisemgangathweni ezifana nezikrufu zomatshini kunye nazo zonke iintlobo zezikrufu zomatshini zobhedu.

Imveliso yethu ingasetyenziswa kwifenitshala yeofisi, kushishino lweenqanawa, kuloliwe, kulwakhiwo, kushishino lweemoto. Ngezicelo ezahlukeneyo ezifanelekileyo kumacandelo ahlukeneyo, imveliso yethu ivelele ngomgangatho wayo ogqwesileyo—yenziwe ngezixhobo zekhwalithi ephezulu kunye neendlela eziphambili zemveliso ukuqinisekisa ukuqina nokusebenza kakuhle. Ngaphezu koko, sigcina impahla eninzi ngamaxesha onke, ukuze ukonwabele ukuhanjiswa ngokukhawuleza kwaye uphephe ukulibaziseka kwiiprojekthi zakho okanye kwimisebenzi yeshishini, nokuba ingakanani na iodolo.

Inkqubo yethu yokuvelisa ichazwa bubuchule obugqwesileyo—sixhaswa bubuchwepheshe obuphambili kunye neengcali zezobugcisa, siphucula yonke inyathelo lemveliso ukuqinisekisa ukuchaneka kunye nokugqwesa kuyo yonke imveliso. Sinyanzelisa imigaqo engqongqo yokulawula umgangatho engashiyi ndawo yokuphazamiseka: izinto eziluhlaza zijongwa ngokungqongqo, iiparameter zemveliso zijongwa ngokusondeleyo, kwaye iimveliso zokugqibela zivavanyelwa umgangatho ngokupheleleyo. Siqhutywa kukuzinikela ekugqweseni, sizama ukwenza iimveliso zeprimiyamu ezibalaseleyo kwimarike ngomgangatho wazo ophezulu kunye nexabiso elihlala ixesha elide.